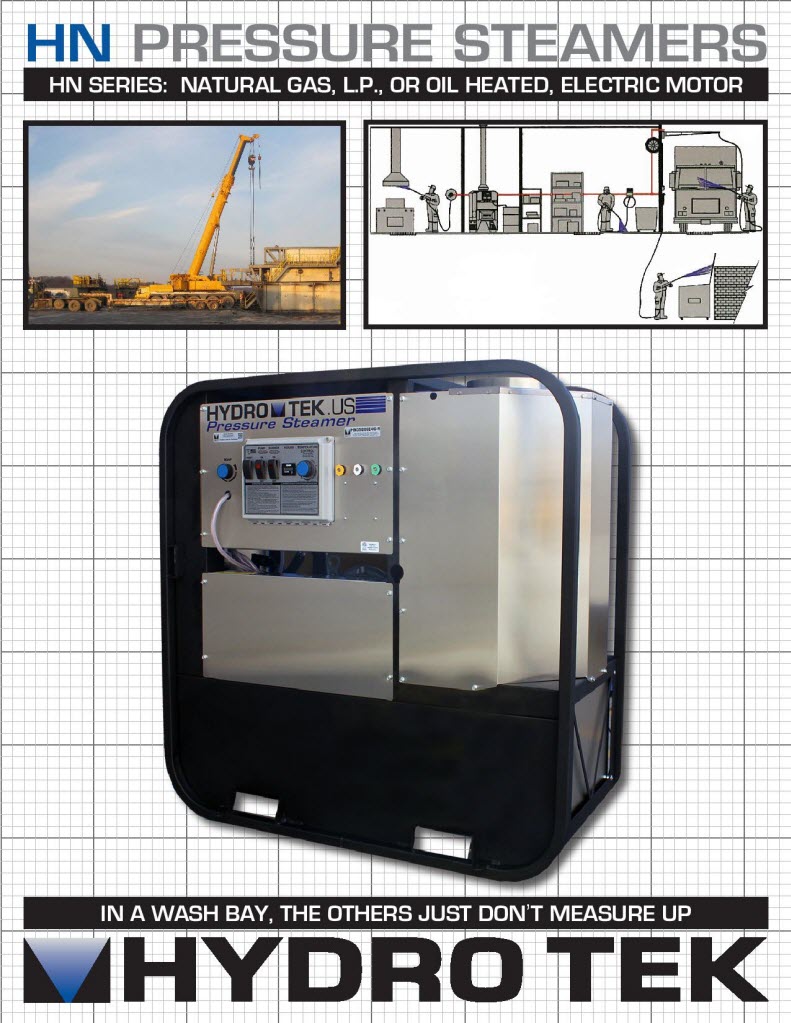

Description

Made in the USA for industrial use, the HN Series is a stationary hot water pressure washer that is powered by electricity and heated by your choice of natural gas, propane or diesel. This allows you to install indoors and have hot water on demand in your wash bay at your facility. These models include stainless steel panels, industrial duty motors and pumps and a lifetime heating coil warranty.

Features:

Ready to work when you are:

No need to fill fuel tanks or hunt down a water supply when machine is directly plumbed into natural gas and water lines. The pressure washer can be housed indoors, away from the elements, while installing wash stations remotely outdoors.

Clean and Efficient Heating System:

24v automatic, electronic ignition on low emission natural gas burner. Liquid Propane conversion option or diesel heated option is available on any model.

SpiraLast™ Coil:

The coil is a Hydro Tek manufactured SpiraLast™ heating coil. Robotically fused ½” schedule 80 steel pipe is cold rolled to protect the steel pipe from fatigue and the spiral coil is then surrounded by ceramic insulation and stainless enclosure with double-wall end caps. Ask your dealer about the Lifetime Coil Warranty.

Belt Driven pump:

Low RPM drive – cooler, quieter, continuous duty performance. These industrial triplex pumps feature ceramic plungers for long life. EZ Align™ pump rail system for belt tensioning with a simple adjustment

bolt.

NEMA4 Water Tight Electrical Box:

ETL certified to UL1776 Class 2 for use in wash-down area, exceeds industry standards. Special Hydro Tek control box features easy to use controls and provides instant access to electronics. Standard

diagnostic indicators ensure optimal system performance. Dual voltage switch on most 230v models allows you to simply flip a switch to change to 208v power supply.

Bypass Cool System:

Worry free pump cooling system prevents pump from overheating with system designed pump bypass feature.

Durable Frame Construction:

Welded, powder coated steel, pro-tect-it frame for durability with rustproof stainless coil wrap and front panels. Forklift slots and overhead lifting points to safely reposition machine. Frame integrated hold down tabs.

Stainless steel frame option as well as an option for a removable, stainless back panel available.

Best in Class accessibility:

Easy-remove panels on an open frame design with open backside gives you full access to all components, including EZ Align™ belt tensioning system, electrical box, and burner igniter for efficient preventative maintenance checks.

More Standard Features:

- Detergent flow metering at full pressure

- Heavy duty industrial motor with standard thermal overload protection.

- Adjustable temperature up to 250°F with steam setting

- Burst disc technology for operator safety

- Rustproof float tank to regulate incoming water ensuring consistent system performance

- Heavy duty hose, wand, and trigger gun and quick connect nozzles

- Remote Ready: Choose an on/off timer remote option or a full function remote option for complete control from the wash site.

Optional Accessories:

Wall mount hose reel, additional wash station remotes, draft diverter, full-feature wall mount remote, 30-min shut off timer, hour meter, downstream soap injection, stainless steel frame, stainless panel wrap kit

Additional information for SCAQMD Permits for customers in Southern California:

http://www.aqmd.gov/home/permits#Guidelines%20and%20Policies

These links detail the exemptions and certifications that our equipment falls within.

Specifications

| Model | PSI | GPM | Temp. | HP | Voltage |

| HN20004E2G | 2000 | 3.9 | 250F | 5 | 208/230v 1ph 20a |

| HN25004E2G | 2500 | 3.8 | 250F | 6.5 | 230v 1ph 29a |

| HN25004E3G | 2500 | 3.8 | 250F | 7.5 | 208/230v 3ph 22a |

| HN25004E4G | 2500 | 3.8 | 250F | 7.5 | 460v 3ph 11a |

| HN30004E2G | 3000 | 3.9 | 250F | 8 | 208/230v 1ph 37a |

| HN30004E2C | 3000 | 3.9 | 250F | 8 | 208/230v 1ph 42a |

| HN35005E3G | 3500 | 4.3 | 250F | 10 | 208/230v 3ph 29a |

| HN35005E3C | 3500 | 4.3 | 250F | 10 | 208/230v 3ph 29a |

| HN35005E4G | 3500 | 4.3 | 250F | 10 | 460v 3ph 15a |

| HN35005E4C | 3500 | 4.3 | 250F | 10 | 460v 3ph 15a |

| HN35006E3G | 3500 | 5.5 | 200F | 15 | 208/230v 3ph |

| HN35006E4G | 3500 | 5.5 | 200F | 15 | 460v 3ph |

NOTE: Any HN series model can be ordered as a Propane or Diesel heated, stationary pressure washer

SM Series: Compact, Portable, Gas Powered, Diesel Heated

SM Series: Compact, Portable, Gas Powered, Diesel Heated SS Series: Mobile Wash Skids - Compact, Gas Powered, Diesel Heated

SS Series: Mobile Wash Skids - Compact, Gas Powered, Diesel Heated SC Series: Mobile Wash Skids - Self-Contained, Gas Powered, Diesel Heated

SC Series: Mobile Wash Skids - Self-Contained, Gas Powered, Diesel Heated SC-X Series : Diesel Powered, Diesel Heated for Extreme Duty

SC-X Series : Diesel Powered, Diesel Heated for Extreme Duty HD Series: Compact, Portable, Electric Powered, Diesel Heated

HD Series: Compact, Portable, Electric Powered, Diesel Heated HP Series: Hot Water Pressure Washer - Portable Electric, Diesel Heated with Exceptional Heat Output

HP Series: Hot Water Pressure Washer - Portable Electric, Diesel Heated with Exceptional Heat Output HN Series: Stationary, Electric Powered, Natural Gas, LP or Diesel Heated

HN Series: Stationary, Electric Powered, Natural Gas, LP or Diesel Heated CPS Series: Cold Water Pressure Washer

CPS Series: Cold Water Pressure Washer Pressure Washer Surface Cleaner - Hydro Twister®

Pressure Washer Surface Cleaner - Hydro Twister® Hydro Twister® Convertible Undercarriage Surface Cleaner

Hydro Twister® Convertible Undercarriage Surface Cleaner Pressure Washer Hose Reels

Pressure Washer Hose Reels Hot Link Hot Water Generator

Hot Link Hot Water Generator Muck Scupper & Sludge Pump

Muck Scupper & Sludge Pump High Reach Wash Pole

High Reach Wash Pole Completely Self Contained, Gas Powered Vacuum Recovery System

Completely Self Contained, Gas Powered Vacuum Recovery System Electric Powered Water Evacuation System with Pump Out

Electric Powered Water Evacuation System with Pump Out ProTowWash® Portable Commercial Pressure Washer Trailers

ProTowWash® Portable Commercial Pressure Washer Trailers Hydro Tek Tank Skid Mounted Pressure Washers

Hydro Tek Tank Skid Mounted Pressure Washers Tow & Stow Transporter

Tow & Stow Transporter Portable Recycle Systems for Truck or Trailer Mount

Portable Recycle Systems for Truck or Trailer Mount