Description

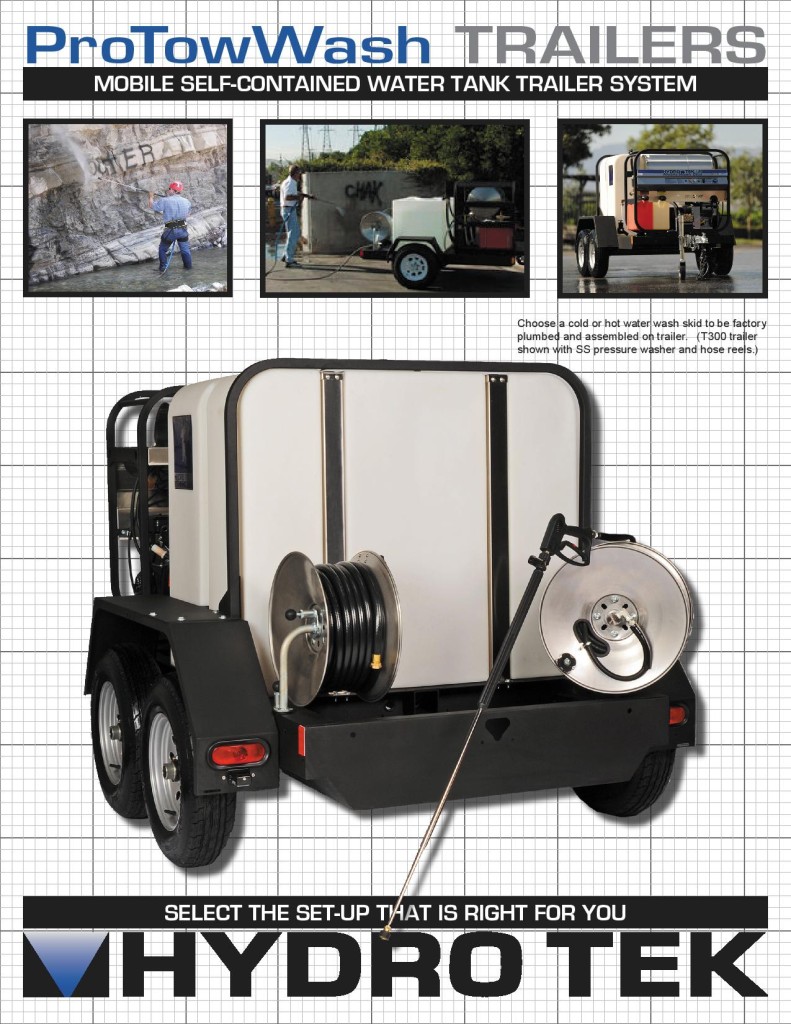

Hydro Tek has been a pioneer in manufacturing commercial trailer pressure washers. Hydro Tek ProTowWash™ pressure washer trailers are engineered and designed specifically for industrial and commercial applications to compliment a hot or cold water industrial & commercial pressure washer. A trailer mounted pressure washer allows you to offer additional services and functionality that you do not have with a standard unit. The portable pressure washer trailer allows you to take your pressure washing equipment directly to your jobsite, regardless of how remote it might be. It is a completely self-contained package with a water tank and trailer mounted pressure washer. Each portable pressure washer trailer is completely customize-able for your specific cleaning job.The ProTowWash™ trailer mounted pressure washer is your mobile solution that hooks up quickly and promotes a professional image of your business.

Commercial Trailer Mounted Pressure Washer Features:

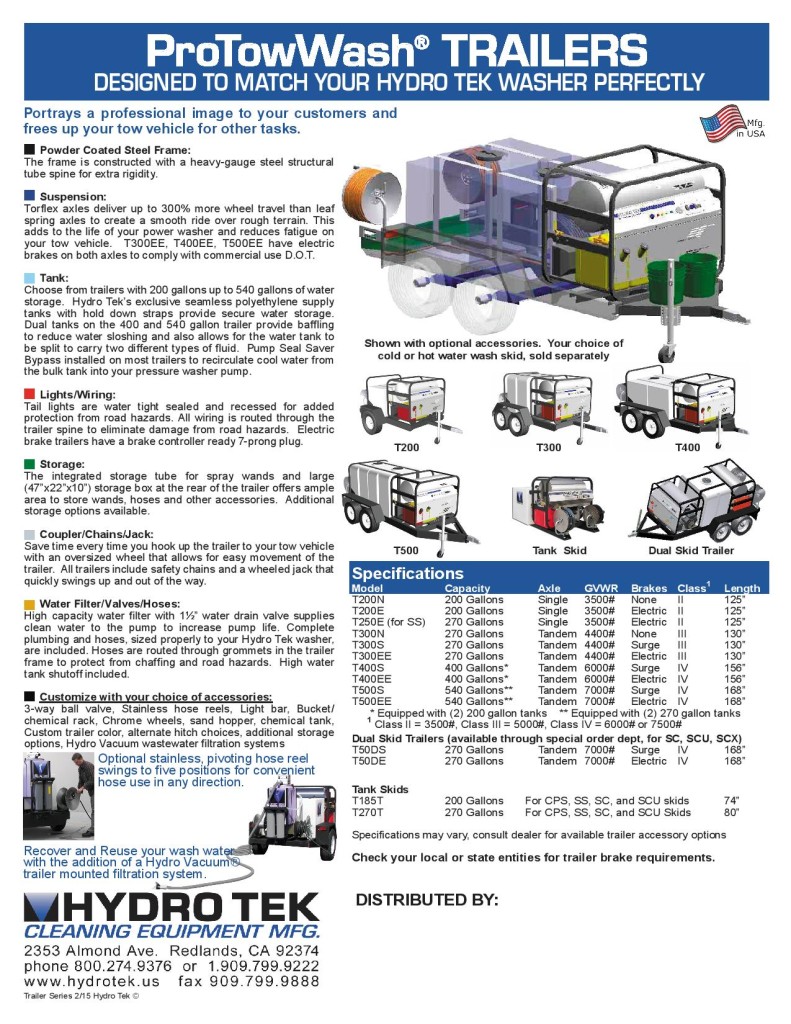

Powder Coated Steel Frame:

The frame is constructed with a heavy-gauge steel structural tube spine for extra rigidity.

Suspension:

Torflex axles deliver up to 300% more wheel travel than leaf spring axles to create a smooth ride over rough terrain. This adds to the life of your pressure washer and reduces fatigue on your tow vehicle. T300EE, T400EE, T500EE pressure washer trailers have electric brakes on both axles to comply with commercial use D.O.T.

Tank:

Choose from pressure washer trailers with 200 gallons up to 540 gallons of water storage. Hydro Tek’s exclusive seamless polyethylene supply tanks with hold down straps provide secure water storage. Dual tanks on the 400 and 540 gallon trailer provide baffling to reduce water sloshing and also allows for the water tank to be split to carry two different types of fluid. Pump Seal Saver Bypass installed on most commercial trailer mount pressure washers to recirculate cool water from the bulk tank into your pressure washer pump.

Lights/Wiring:

Tail lights are water tight sealed and recessed for added protection from road hazards. All wiring is routed through the trailer spine to eliminate damage from road hazards. Electric brake pressure washer trailers have a brake controller ready 7-prong plug.

Storage:

The integrated storage tube for spray wands and large (47”x22”x10”) storage box at the rear of the portable trailer offers ample area to store wands, hoses and other accessories. Additional storage options available.

Coupler/Chains/Jack:

Save time every time you hook up the trailer to your tow vehicle with an oversized wheel that allows for easy movement of the trailer. All trailer mounted pressure washers include safety chains and a wheeled jack that quickly swings up and out of the way.

Water Filter/Valves/Hoses:

High capacity water filter with 1½” water drain valve supplies clean water to the pump to increase pump life. Complete plumbing and hoses, sized properly to your Hydro Tek commercial pressure washer, are included. Hoses are routed through grommets in the trailer frame to protect from chaffing and road hazards. High water tank shutoff included.

Customize your commercial trailer pressure washer with your choice of accessories:

3-way ball valve, Stainless hose reels, Light bar, Bucket/chemical rack, Chrome wheels, sand hopper, chemical tank, Custom trailer color, alternate hitch choices, additional storage options, Hydro Vacuum wastewater filtration systems.

Specifications

| Model | Capacity | Axle | GVWR | Brakes | Class | Length |

| T200N | 200 Gallons | Single | 3500# | None | II | 125” |

| T200E | 200 Gallons | Single | 3500# | Electric | II | 125” |

| T250E (for SS) | 270 Gallons | Single | 3500# | Electric | II | 125” |

| T300N | 270 Gallons | Tandem | 4400# | None | III | 130” |

| T300S | 270 Gallons | Tandem | 4400# | Surge | III | 130” |

| T300EE | 270 Gallons | Tandem | 4400# | Electric | III | 130” |

| T400S | 400 Gallons | Tandem | 6000# | Surge | IV | 156” |

| T400EE | 400 Gallons | Tandem | 6000# | Electric | IV | 156” |

| T500S | 540 Gallons | Tandem | 7000# | Surge | IV | 168” |

| T500EE | 540 Gallons | Tandem | 7000# | Electric | IV | 168” |

Video

There is currently no video for this product, check out our YouTube Channel for other videos:

SM Series: Compact, Portable, Gas Powered, Diesel Heated

SM Series: Compact, Portable, Gas Powered, Diesel Heated SS Series: Mobile Wash Skids - Compact, Gas Powered, Diesel Heated

SS Series: Mobile Wash Skids - Compact, Gas Powered, Diesel Heated SC Series: Mobile Wash Skids - Self-Contained, Gas Powered, Diesel Heated

SC Series: Mobile Wash Skids - Self-Contained, Gas Powered, Diesel Heated SC-X Series : Diesel Powered, Diesel Heated for Extreme Duty

SC-X Series : Diesel Powered, Diesel Heated for Extreme Duty HD Series: Compact, Portable, Electric Powered, Diesel Heated

HD Series: Compact, Portable, Electric Powered, Diesel Heated HP Series: Hot Water Pressure Washer - Portable Electric, Diesel Heated with Exceptional Heat Output

HP Series: Hot Water Pressure Washer - Portable Electric, Diesel Heated with Exceptional Heat Output HN Series: Stationary, Electric Powered, Natural Gas, LP or Diesel Heated

HN Series: Stationary, Electric Powered, Natural Gas, LP or Diesel Heated CPS Series: Cold Water Pressure Washer

CPS Series: Cold Water Pressure Washer Pressure Washer Surface Cleaner - Hydro Twister®

Pressure Washer Surface Cleaner - Hydro Twister® Hydro Twister® Convertible Undercarriage Surface Cleaner

Hydro Twister® Convertible Undercarriage Surface Cleaner Pressure Washer Hose Reels

Pressure Washer Hose Reels Hot Link Hot Water Generator

Hot Link Hot Water Generator Muck Scupper & Sludge Pump

Muck Scupper & Sludge Pump High Reach Wash Pole

High Reach Wash Pole Completely Self Contained, Gas Powered Vacuum Recovery System

Completely Self Contained, Gas Powered Vacuum Recovery System Electric Powered Water Evacuation System with Pump Out

Electric Powered Water Evacuation System with Pump Out ProTowWash® Portable Commercial Pressure Washer Trailers

ProTowWash® Portable Commercial Pressure Washer Trailers Hydro Tek Tank Skid Mounted Pressure Washers

Hydro Tek Tank Skid Mounted Pressure Washers Tow & Stow Transporter

Tow & Stow Transporter Portable Recycle Systems for Truck or Trailer Mount

Portable Recycle Systems for Truck or Trailer Mount